Oilfield garbage and oily sludge contain toxic and harmful substances such as sulfide, benzene series, phenols, anthracene, pyrene, etc., and some hydrocarbon substances contained in crude oil have carcinogenic, teratogenic, and mutagenic effects. Oilfield garbage sludge has been classified as hazardous solid waste (HW08) by the state and is included in hazardous waste for management With the pyrolysis process, the raw materials can be directly processed without excessive pretreatment, which reduces the link of pollution. Because the heating temperature can be controlled by itself, the oil content of the treatedcarbon residue can reach the harmless emission standard required by the country-3%o (the original standard is 5%).

Anti-sticking No coking

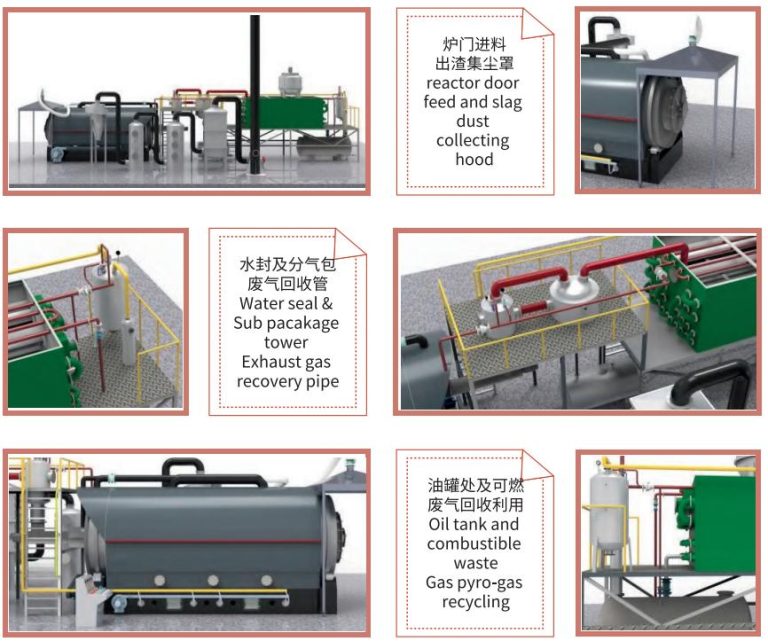

Oilfield garbage sludge usually contains components such as gums and asphalt, which are prone to a series of thorny problems such as wall sticking and coking during heating treatment. Not only will it affect production efficiency and increase the difficulty ofcleaning, it will also affect the service life of the equipment and cause safety hazards. The technical difficulty and core of dealing this kind of raw materials is the anti-sticking and anti-coking treatment. The wall scraping device developed exclusively by Ruilong Company can efficiently clean the innerwall of the reactor, truly solve the problem of wall sticking and coking, and realize the reduction, resource utilization and harmless treatment of oilfield garbage and sludge.

* On behalf of required, please carefully fill in the following, we will contact you in time.