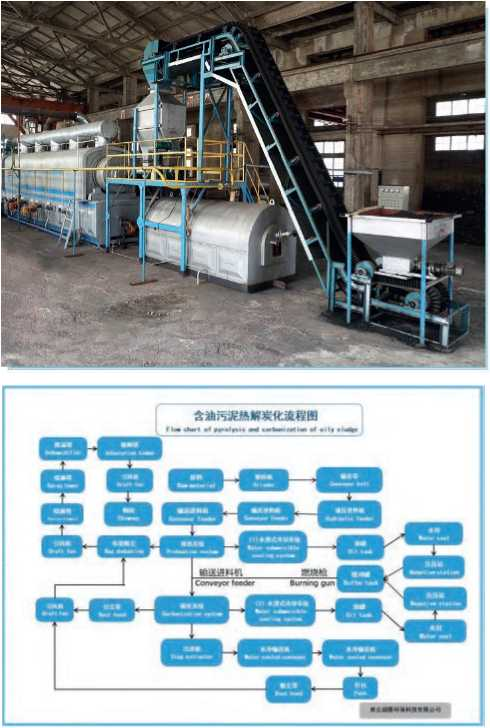

In the process of oil extraction, due to the influence of natural or human factors, a large amount of crude oil will be leaked. These ground crude oils are mixed with gravel, sand, weeds, etc. to form oily sludge. In addition, the natural sedimentation of crude oil in the tankwill also produce a large amount of sludge sand. Because of the continuous and rapid development of the petroleum industry for many years, not only a steady stream of fresh sludge is produced, but also a huge amount of old sludge needs to be processed. Continuous sludge pyrolysis equipment can achieve high efficiency, low energy consumption, and more stable realization of sludge reduction, harmlessness, and resource disposal.

Technical Tackling

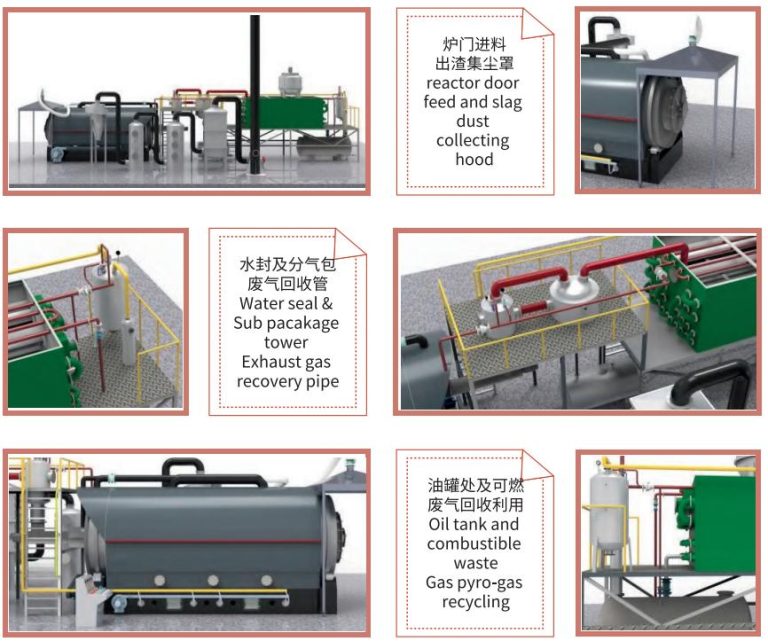

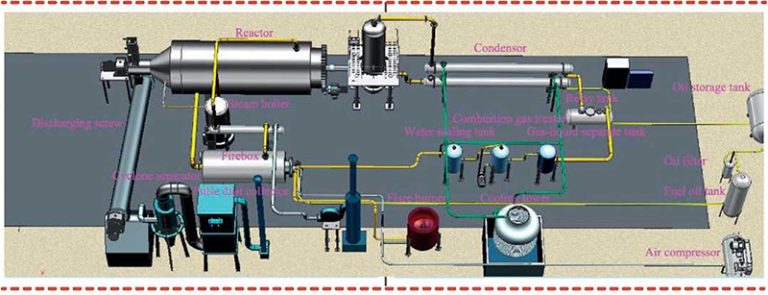

The reactor is equipped with an exclusive design anti-sticking wall device, centered on the four-point supporting shaft, and multiple rotatable wall scraping units are suspended. The wall scraping unit is inclined at a specific angle, and there is a toothed scraper at the bottom. During production, the wall scraping unit will rotate slightly due to the large counterweight and always clean the inner wall of the furnace at the bottom. The device can effectively prevent coking due to phase separation of condensate and coking due to gravity sedimentation. When discharging slag, the barrier rod can limit the freedom of the wall scraping unit to a certain extent. Because the scraper at the bottom is in the shape of a spiral ribbon, it can also promote the carbon black to move to the slag discharging end to complete the slag discharge.

* On behalf of required, please carefully fill in the following, we will contact you in time.