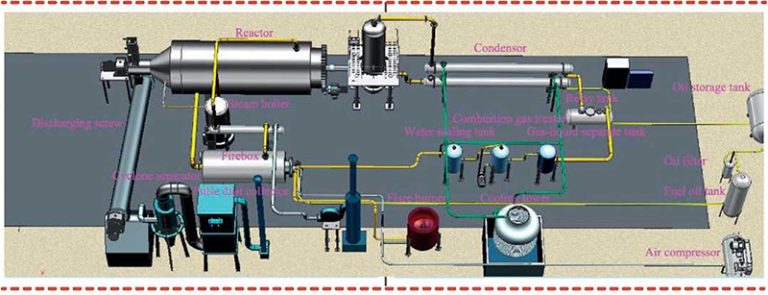

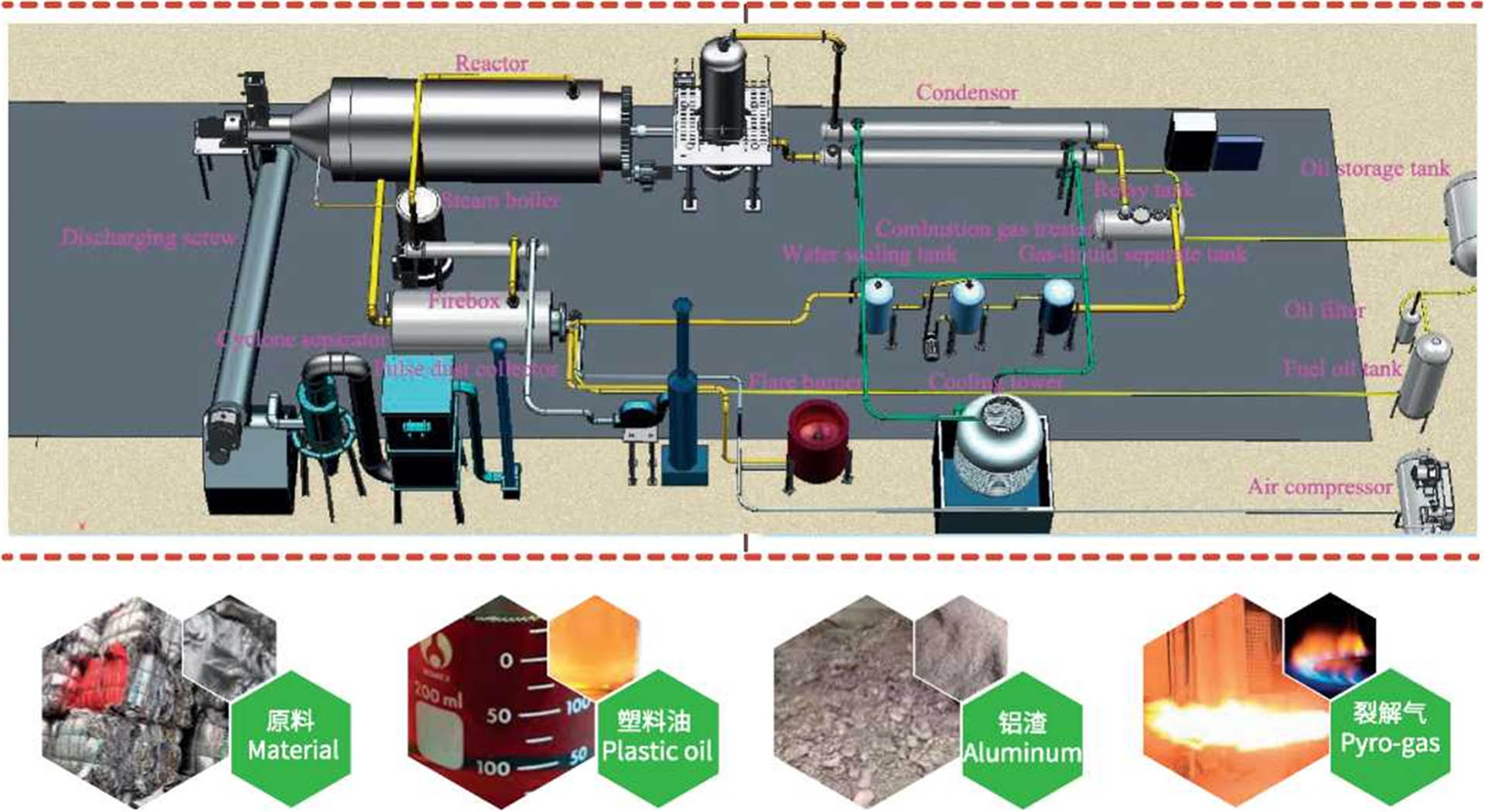

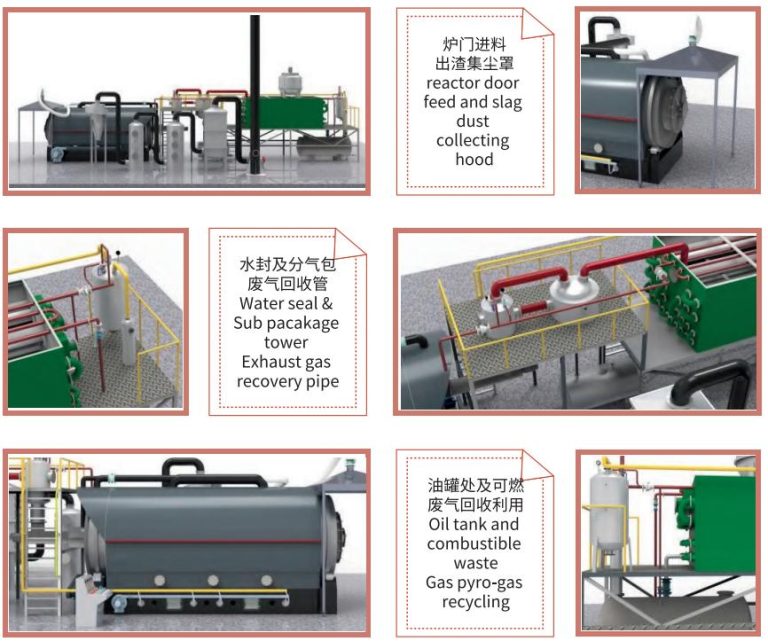

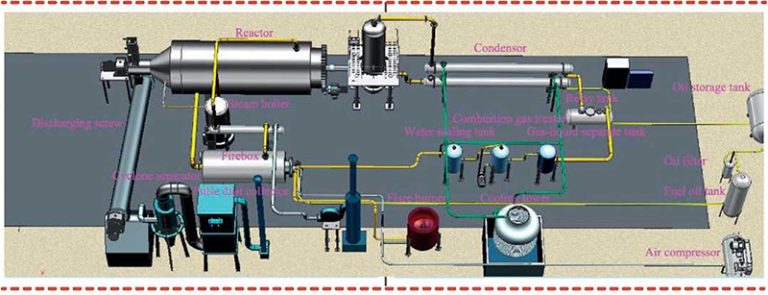

Waste aluminum-plastic can be extracted from fuel oil and aluminum powder through pyrolysis equipment. This process does not need to finely remove impurities such as sand, water, iron wire and other impurities in the raw materials. It can be processed directly or after simple compression and bundling, through automatic loading the feeder transports the raw materials to the reactor. The heating can be fuel oil extracted from aluminum plastic or diesel oil When the temperature rises to about 120°, the plastic part of the aluminum plastic can distill out the oil vapor mixture. The oil and gas are condensed through the multi-stage separator and the cooling system to obtain better quality fuel oil, and the aluminum will remain in the reactor.

Terminal products produced from waste aluminum plastics: aluminum plastic oil is also called plastic oil, fuel oil, which can be directly used for heating of pyrolysis equipment, or sold to factories as boiler fuel, such as ceramic factories, glass factories, cement factories, and heating stations, power plants, etc.Or deep processing with refining equipment; aluminum foil can be deep processed into aluminum ingots, fireworks and firecrackers, etc. The crude aluminum blocksare crushed to make aluminum powder; the pyrolysis gas can be sent back to the burner for heating, saving energy and reducing emissions.

* On behalf of required, please carefully fill in the following, we will contact you in time.