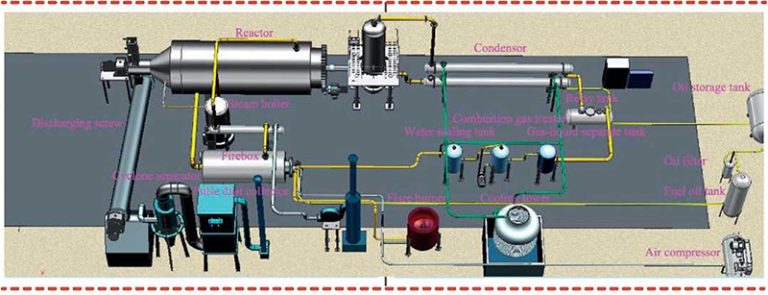

Thermal pyrolysis equipment is used for soil thermal desorption treatment, and the production process is carried out under low temperature, normal pressure, and hypoxia conditions. Not only can the generation of dioxins be avoided, but also more energy-saving, more environmentally friendly and safer. The pyrolysis equipment can be operated by a single unit or in multiple units, and the processing capacity is more flexible; the equipment purchase cost is relatively low, and the investment risk is smaller; the equipment production and operation cost is lower and the efficiency is higher.

Thermal desorption technology refers to heating the organic impurities in the soil to a sufficient temperature through direct or indirect heat exchange under vacuum conditions orwhen the carrier gas is introduced, so that the organic impurities can be volatilized or separated from the polluted medium. The process of entering the gas processing system. The process can selectively convert it from mutual phase to another phase by adjusting heating temperature and residence time, etc., and there is no damage to organic compounds during the repair process. .By controlling the temperature of the thermal desorption system and the residence time of the contaminated soil, the volatilization can be selectively enabled without chemical reactions such as oxidation and decomposition. It can effectively remove volatile organic matter, and can also effectively remove semi-volatile or difficult-to-volatile organic impurities with high boiling points and difficult to decompose. For organic impurities rich in a variety of different boiling points, it can be heated at one time to achieve the repair target value.

* On behalf of required, please carefully fill in the following, we will contact you in time.