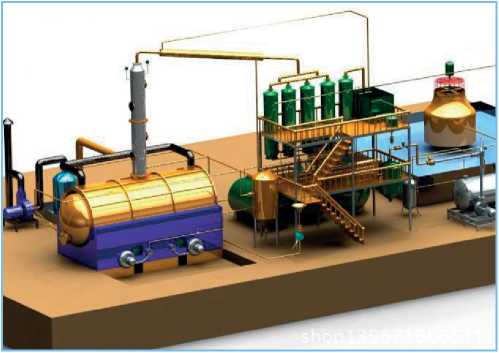

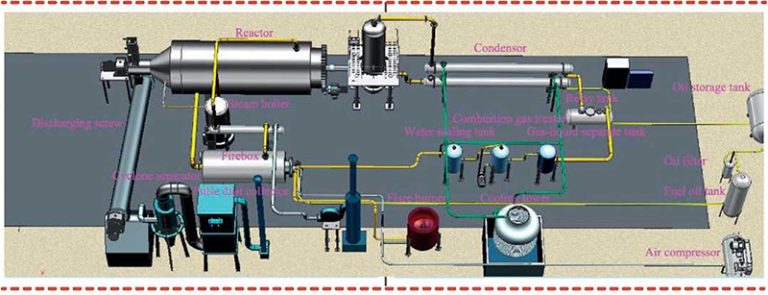

Pyrolysis equipment can be divided into batch type and continuous type. The main difference between the two types is the feeding & discharging method and the heating & cooling system. Batch type equipment is a sequential batch operation, which is a one-time filling and stopped production cooling mode; continuous equipment is continuous feeding & discharging, and heating for a long time does not need to stop the reactor for cooling. The continuous equipment realizes automatic, continuous, high-efficiency, and low-energy production, and successfully reduces, harmless, and recycles various organic solid waste and hazardous waste. The continuous treatment process not only conforms to the development trend of the industry, has high safety, environmental protection and stability, but also meets the requirements of today’s policies.

* On behalf of required, please carefully fill in the following, we will contact you in time.