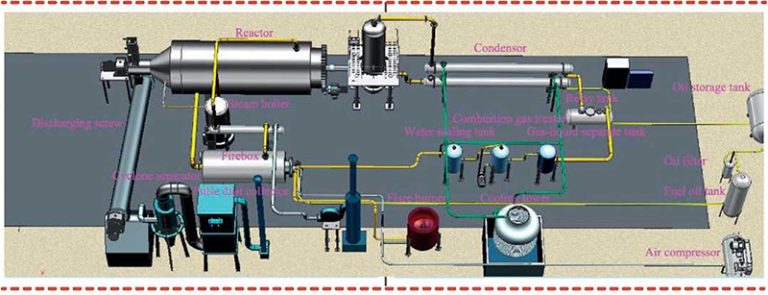

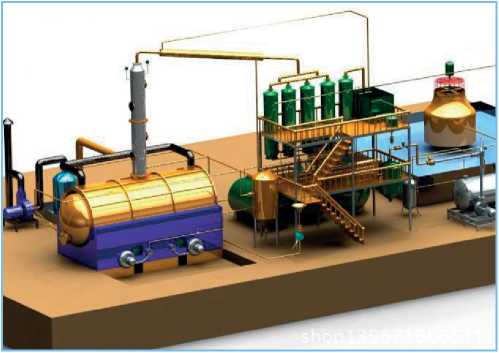

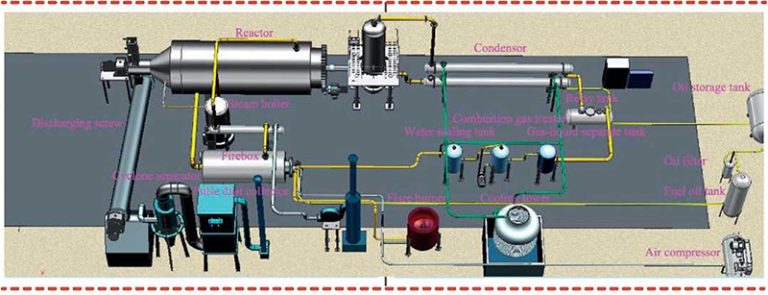

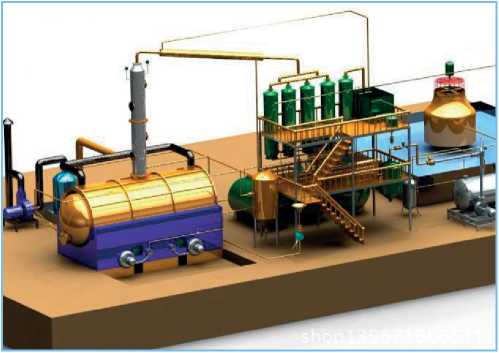

The pyrolysis production process is under low temperature, normal pressure, and hypoxia; multiple emergency vents are set on the equipment; temperature gauges and pressure gauges can remotely data to the control cabinet, which is convenient for manual and mechanical dual monitoring. There are alarms and emergency braking devices on the control cabinet.

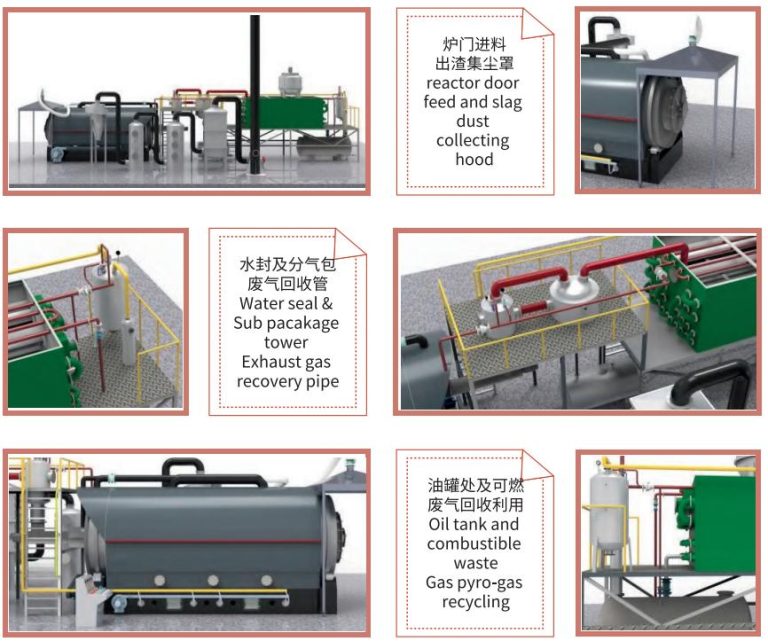

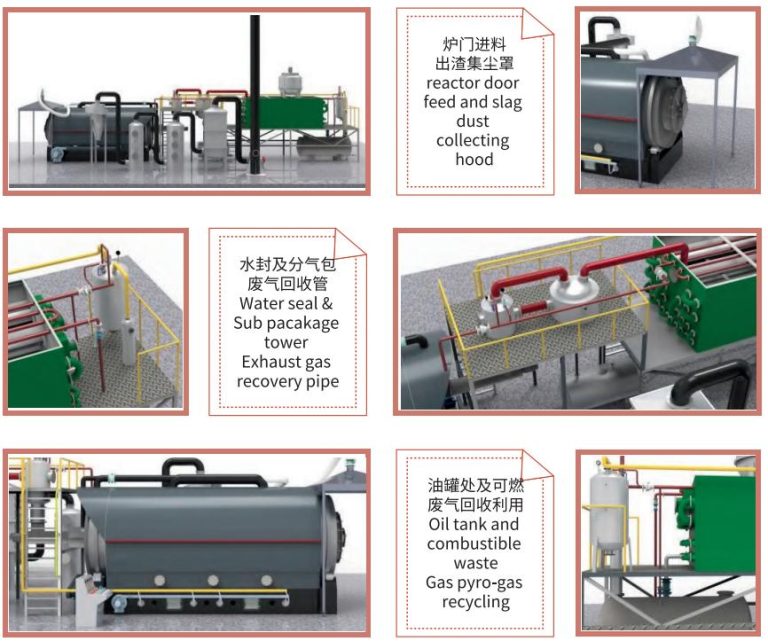

The waste gas mainly comes from two aspects: 1. The flue gas produced by heating the fuel; 2. The non condensable gas (cracked gas) decomposed after the raw material is thermally cracked. Non-condensable gas is generally weakly acidic and corrosive to a certain extent. It enters the flue gas treatment system after being fully burned through the safety device water seal and gas nozzle to achieve energy saving and emission reduction. Before the flue gas is discharged, it enters a series of desulfurization and dust removal systems for treatment, and the final discharge can reach the relevant standards of GB 13271-2001.

The equipment that uses water on the equipment mainly includes the following: 1. Water seal; 2. Desulfurization and dust removal tower; 3. Cooling system. The first two places are used for filtering and cooling of oil and gas or flue gas, and the water will be lost by evaporation. Regular water replenishment is enough, no external discharge is required, and no water pollution will be caused. The water used in the cooling system is only used to cool the outside of the pipeline, because it is notin contact with other pipelines, and there is no pollution.

After the organic solid waste is treated by pyrolysis equipment, the remaining residue in the furnace is carbon black or ash. If it is tire carbon black, it can be used as a raw material for the production of industrial carbon black; it can be mixed with fly ash and used as a raw material for making fly ash bricks (an environmentally friendly building material); or it can be made into carbon rods as fuel; After carbon black deep processing equipment, it is used as raw material or adsorbent for the production of rubber products. Other ash is mainly used as fuel.

Safety and environmental protection work is related to the country’s economic development and social harmony, the company’s long-term development, normal operations, and the happiness and well-being of all employees. Doing a good job in safety and environmental protection is a responsibility, a requirement, but also a political and overall situation.The safety, environmental protection and stability of the equipment is also the top priority of our company’s research and development.

* On behalf of required, please carefully fill in the following, we will contact you in time.