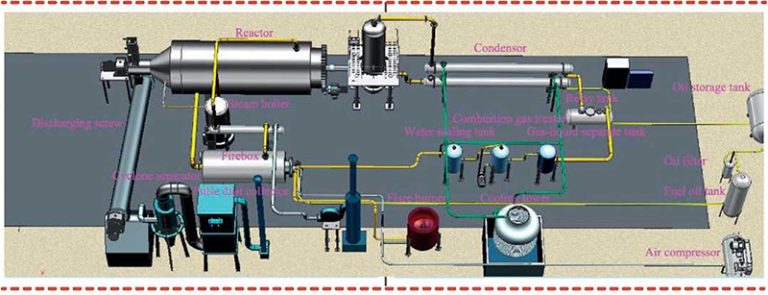

| Item | 15 T fully continuous waste tyre pyrolysis plant |

| Type | XFLJ–15 |

| Capacity | 15T/D |

| Operating

temperature |

≤650° |

| Material | Q345R |

| Fuel consumption in start | 300 kg

|

| Fuel consumption in operation | 0

(the syn gas from the system be burnt by the system itself) |

| Heating way | Hot air circulation heating |

| Tire requirement | Tyre piece ≤20mm |

| Working pressure | Normal pressure |

| Methods of flame retardant | Nitrogen Blow |

| Total power | 90 kw |

| Running power | 80 kw/h |

| Boundary

dimension |

14000mm(L) × 2400mm(W) × 4000mm(H) |

| Floor space | 36000 mm ×3500 mm |

| The highest install elevation | 7000 mm |

| Labor | 1-2 people |

| Working life | 5-7 year |

* On behalf of required, please carefully fill in the following, we will contact you in time.