As the most common solid waste with huge reserves, and because of the fixed chemical composition of tires, the input-output ratio is relatively stable. Waste tires occupy the primary position of raw materials processed in the pyrolysis industry. Disposal of waste tires can decide whether to pre-treat by themselves, and 100% effective utilization can be achieved through the thermal cracking process, and the products generated are all renewable products with high economic value.

Tire oil has a calorific value of ~10200 calories, a density of about 0.9, strong fluidity, and a quality close to SCT180 heavy oil. It can be used as ship driving oil, and it can also be used as a non-renewable energy substitute such as crude oil and coal.

It can be used as a filler for the production of low-end rubber products; as a filler and additive for asphalt and sealing products; as a commercial carbon black/industrial carbon black after deep processing; directly burned as a coal substitute.

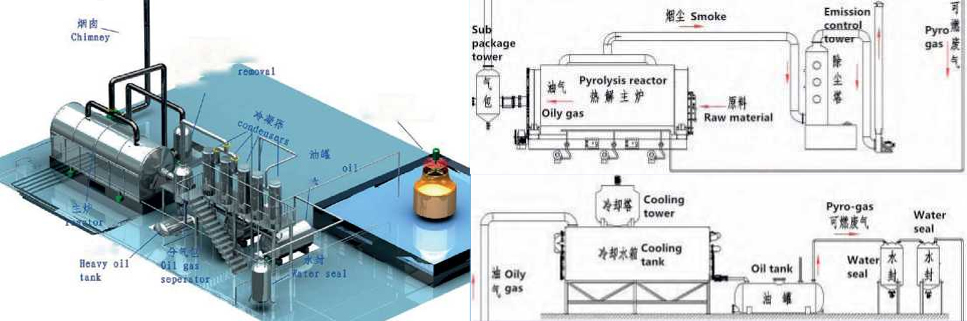

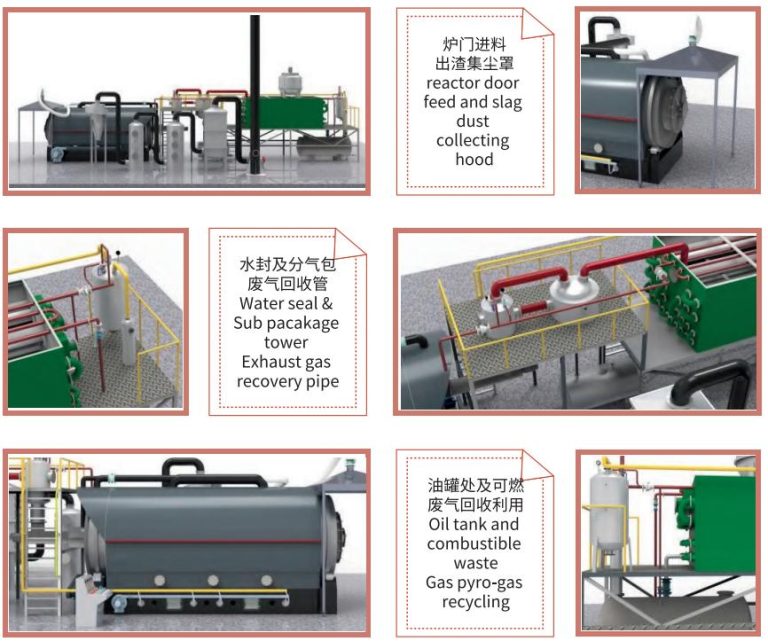

The steel wire recycled from the tire can be used as a high-quality raw material for the production of springs, or used to make new tire steel wires, or directly sold to steel mills. After the temperature rises to 150°C, a large amount of gases that cannot be liquefied at room temperature will be produced-OC4. These gases are filtered by the safety flame arrester and sent back to the heating system for combustion, realizing the comprehensive utilization of energy recycling.

* On behalf of required, please carefully fill in the following, we will contact you in time.